Detail

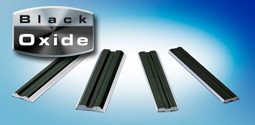

14.02.2011 |Black Oxide - System Planer Knives in special HSS with optimized hard cutting edge

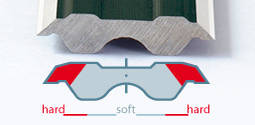

Optimized distribution of hardness

The unique manufacturing process maneuvers hardness to where it belongs: the cutting edge. The core of the knife remains soft to help protect against breakage and to also increase the ease of an eventual straightening.

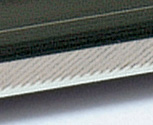

Polished cutting edge

For an extra-aggressive cut in the wood, the cutting edge has a second, partial polish grind.

Black Oxide Surface

The thin black surface layer of ferric oxide, only nanometers thick, runs across the top and bottom. This improves corrosion resistance and prevents early rusting.

Eco-friendly

As compared to knives ground from solid steel bars, the special manufacturing of this product consumes up to 30% less raw material, helping to avoid waste. Additionally, compared to traditional production methods, the energy consumption is up to 50% lower. These eco-friendly features help save the environment.

Highest European quality

As always with TIGRA, our knives are of the highest European quality, manufactured on the most modern production lines.

Real High Speed Steel

Real HSS for a long lifetime!

Excellent pricing

In addition to these advantages, we offer the „Black Oxide“ knives at an unbeatable price!